Smart tech harnessed to bring old trades into 21st century

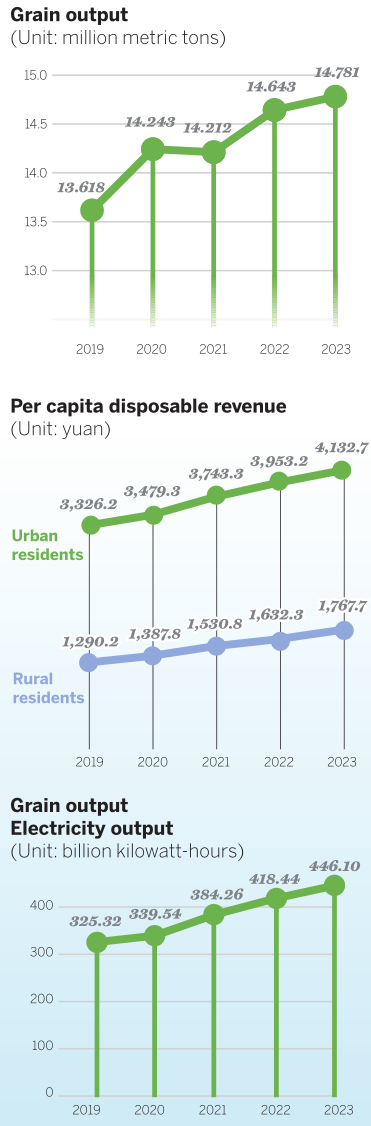

Shanxi is promoting an industrial transformation campaign to upgrade its traditional coal mining and related heavy industries, as well as to diversify its economy by fostering emerging industries.

This seems a difficult mission considering the local economy has been dominated by coal mining for many decades.

However, the rapid development of new sciences and technologies, especially digital and intelligent technologies, is now offering an efficient solution.

At 500 meters underground, robots monitor mining in Xinyuan Coal Mine of Lu'an Chemical Group based in the southeastern Shanxi city of Changzhi. Assisted by 5G technology, the automated inspectors send real-time data to the mining company's control center to monitor safety.

Xinyuan became China's first 5G network-connected coal mine in 2020. Mining managers can view operational situations in 32 underground working scenarios, including coal cutting, conveying, ventilation and gas concentration, via the smart system.

As a pilot in China's coal-mining industry digitalization, Xinyuan has turned four mining shafts and 15 coal-cutting sites into smart facilities.

Tashan Coal Mine, a subsidiary of Shanxi's energy giant Jinneng Holding Group, is another example of smart mining.

In the coal mine's central control room, operators sit by desks with arrays of computers, surrounded by walls of display screens.

With just one click on the computer, underground coal cutters, conveyors and equipment are immediately plugged in. Their real-time images and data flicker across the screens, pumping the coal — which is always referred to as "black gold" — up to the planet's surface.

When talking about the changes brought by smart coal mining, Zhang Xing, an executive of Tashan Coal Mine, said he feels a revolution is occurring.

"We have realized intelligent coal cutting in seven shafts, ensuring a coal recovery rate of up to 90 percent," he said. "This is also increasing safety and improving the in-shaft environment along with a rising efficiency."

Mining workers are the ones most pleased with the improvements in efficiency and safety in their workplaces brought by mining digitalization.

Guo Jinchao, a worker in Jinxinda Coal Industry, a branch company of Shanxi Coking Coal Group, had been working in underground mine shafts for many years.

But now he is working at a control center above the ground, skillfully controlling various mining equipment via a remote operational system.

"The system makes automation possible for coal cutting and conveying," Guo said. "The number of laborers for one shift has been reduced from eight to four and the production efficiency has also increased by 50 percent."

According to Miao Huanli, deputy chief of the Shanxi Energy Bureau, Shanxi was home to 118 smart coal mines and 1,491 smart coal-mining shafts by the end of 2023. The majority of the coal output in the province is now produced by these advanced facilities.

A recent document released by the bureau said that Shanxi will have a total of 200 smart coal mines by the end of this year. It added that all coal mines there will have smart operations by 2027.

In addition to coal mining, related industries like coking and power generation are going smart with the application of digital technologies.

The coking unit of Jinnan Steel Group based in the city of Linfen is an example of the coking industry upgraded with smart technologies.

With the application of digital technologies, the group's coking production is now controlled by an integrated control center. With such a center, a company executive said the laborious coking process, including coal loading, coking, coke quenching and coke unloading, can be virtually controlled by one person with the push of a button.

In addition to the energy industry, almost all sectors in Shanxi are going smart with the help of digital technologies.

Huaxiang Group based in the city of Linfen is an advanced manufacturer of precise metal components for a variety of industries. In 2023, it established its 5G-connected industrial internet network to empower its operations.

"The network has covered all our three industrial parks and is connected with more than 3,000 sets of manufacturing equipment," said Wang Yuan, president of the company. "This allows the automation of all the operational processes, like purchase, production, safety, quality control, sales, equipment maintenance and management of human resources and costs."

In the production facility of automaker Geely in Jinzhong city, digitalized production has contributed to a substantial improvement in efficiency, allowing the completion of a new energy car in 90 seconds at its general assembly plant.

Digitalization has also brought fundamental changes to the agricultural industry.

Gao Zhiqiang, a researcher from Shanxi Agricultural University, for instance, has led a team of agronomists from his university to offer technological services to farmers in the county of Yicheng. Digitalization is part of the solutions the team offers to farmers.

During the summer wheat harvest season in 2023, a farm in Yicheng's Dongguan village — which his team took care of — reported a per-hectare yield of 12.39 metric tons, breaking the record for wheat farming in Shanxi province.

Gao said the team's bid to improve output is based on analysis of data collected from the farming process.

The scientist said the most effective way to increase output and improve quality is the proper use of water and fertilizers. This can be calculated according to the digitally monitored conditions of the farm, such as soil moisture and the level of nutrition in soil, as well as light and heat exposure.

In Shanxi, digital technologies have been widely applied to the tourism, medical care, urban traffic management and administrative service sectors, bringing convenience to local residents and tourists alike.

.png)

.png)

.png)