China's 1st 100-meter-long remote crane put into use at Baogang Group

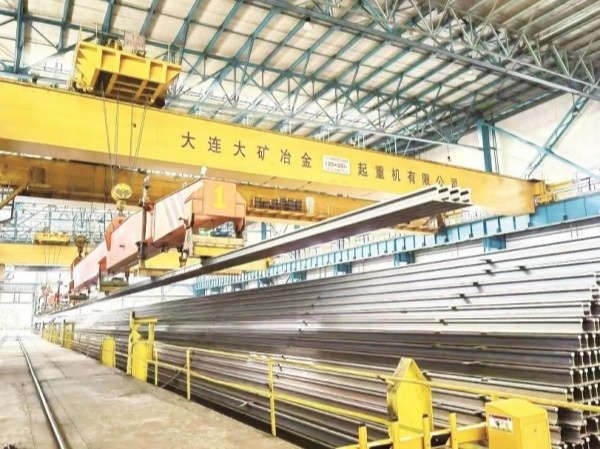

Under remote control by employees, a 100-meter rail is smoothly placed onto the inspection platform. [Photo/Baotou Daily]

China's first 100-meter crane remote centralized control project was recently implemented at Baogang Group and has officially been put into use in the rail beam plant. This project is a significant initiative to promote industrial upgrading and innovation.

According to the head of the crane inspection department at the group's rail beam plant, construction of the project began in March of this year. By building a centralized control center that integrates production operations and equipment maintenance, the project has created a centralized model that reduces manpower and allows one-click operations.

Currently, three finished product warehouse areas on lines 1 and 2, as well as six 100-meter cranes, have fully transitioned to remote, intelligent and centralized control.

Operators can manage the cranes from the centralized control center using high-precision, low-latency monitoring screens and advanced control systems. They can oversee the crane's operating status in real time, facilitating the efficient handling of complex lifting tasks such as storage and loading, thereby improving both productivity and safety.

Additionally, the system features advanced functionalities such as intelligent inventory management, visual recognition, equipment self-diagnosis, and safety control, contributing to the dynamic and efficient management of the rail storage area and transportation vehicles.

Equipment malfunctions can also be prevented and quickly addressed, allowing for comprehensive monitoring and detailed recording of the operational site, ensuring a safe and smooth production process.

Guyang county in Baotou home to stunning sites

Guyang county in Baotou home to stunning sites