- Home

- Media Center

-

Events

- Wuzhen Summit

- Regional Forums

- Practice Cases of Jointly Building a Community with a Shared Future in Cyberspace

- World Internet Conference Awards for Pioneering Science and Technology

- The Light of Internet Expo

- Straight to Wuzhen Competition

- Global Youth Leadership Program

- WIC Distinguished Contribution Award

- Membership

- Research & Cooperation

- Digital Academy

-

Reports

- Collection of cases on Jointly Building a Community with a Shared Future in Cyberspace

- Collection of Shortlisted Achievements of World Internet Conference Awards for Pioneering Science and Technology

- Reports on Artificial Intelligence

- Reports on Cross—Border E—Commerce

- Reports on Data

- Outcomes of Think Tank Cooperation Program

- Series on Sovereignty in Cyberspace Theory and Practice

- Other Achievements

- About WIC

- 中文 | EN

Collection: IIoT WIA-PA technology and system of intelligent oilfield

Introduction

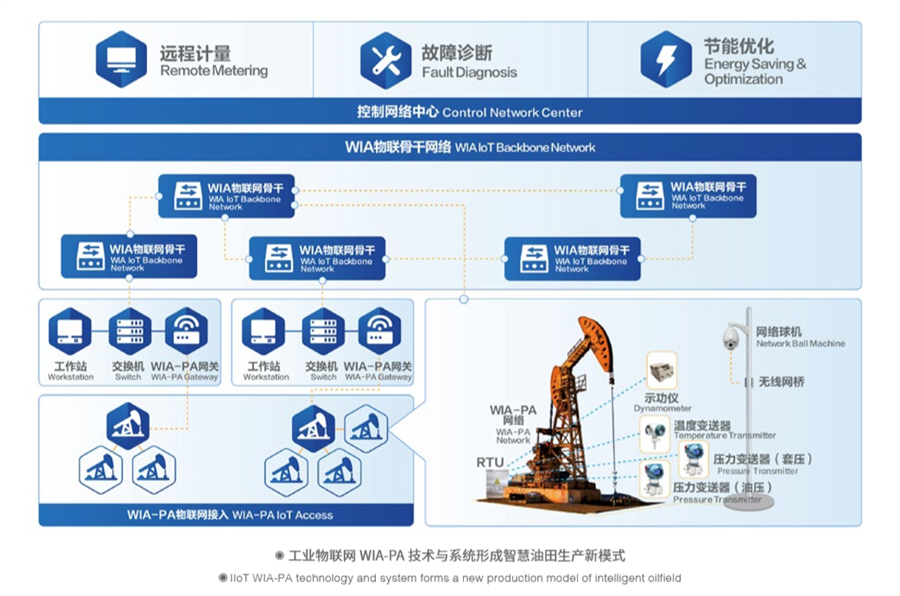

IIoT WIA-PA technology and system of intelligent oilfield breaks through the ultra-large-scale, high-reliability IoT networking technology in extreme environments, publishes a series of international and Chinese standards, develops core chips and ultra-low power consumption instrument terminals, builds an industrial IoT system with full coverage of oilfield production, and forms a new intelligent oilfield production model.

We develop the industrial Internet of Things WIA-PA technical standards and a series of instruments and equipment, and build the IoT system covering all oilfield production processes

Wide-area ultra-large-scale, high-reliability, and high-real-time wireless networking technology: It has achieved international leading indicators of second-level deterministic delay and transmission reliability above 99% for single-gateway thousand-point industrial wireless networks, forming China's only international standard in this field.

Ultra-low power consumption operation technology for instrument terminals adapted to the extreme environment in the wild: Synchronization accuracy reaches the level of microseconds, reaching the best level of similar international products.

Innovation in production measurement mode: The oil well production measurement method based on industrial IoT technology is proposed, which profoundly changes the production measurement mode of a single well in the oilfield, from the original hardware measurement mode to the dynamic, real-time, and accurate soft measurement innovation mode, and greatly reduces the production and operation cost.

Innovation in equipment operation and maintenance mode: The diagram card is used to realize real-time and automatic identification of oil well conditions, and the innovative mode of online diagnosis and predictive operation and maintenance, so as to realize the accurate identification and rapid response of oil well faults.

Innovation in oil production process: Through the collaborative production-injection optimization of oil and water wells, and the intelligent frequency conversion control technology, the innovative oil production process mode of "production and injection coordination, intelligent decision-making and automatic parameter adjustment" is established, which greatly improves the production efficiency of oil wells and effectively reduces the energy consumption of the production system.

The WIA-PA protocol standard has been adopted by CNPC as an industry standard and has been applied on a large scale in CNPC oilfields

In 2019, we signed a strategic cooperation agreement with Daqing Oilfield and Liaohe Oilfield of CNPC to promote the use of WIA-PA technology, carried out the construction of IIoT WIA-PA technology and system digitization project, and achieved digital coverage of oil and water wells in 3-5 years.

At present, WIA-PA has been adopted as an industry standard by CNPC and has been applied on a large scale, covering more than 60,000 oil and water wells and applying more than 200,000 sets of WIA-PA terminal equipment.

The WIA-PA-based production monitoring and optimization control system integrates production monitoring, production optimization, and production management, effectively solves the problem of real-time monitoring of large-scale wide-area distributed production wells in oilfields, plays an important role in the stable production and increase of oilfields, and creates significant social and economic benefits.

It has realized the comprehensive innovation of production measurement, equipment transportation, and oil recovery technology, and formed a new production model of intelligent oilfields.

Shenyang Institute of Automation, PetroChina, and ALLWIN deployed WIA-PA technology and system in Daqing Oilfield and Liaohe oilfield, and realized the comprehensive innovation of production measurement mode, equipment operation and maintenance mode and oil recovery process, greatly improved the intelligent level of oilfield production, increased the average pump efficiency by 1.8%, reduced energy consumption by 8.5%, reduced ineffective and inefficient water injection by 19%. It provides an effective solution to solve the "one difficulty and two high" problems.

By constructing the IIoT system with full coverage of oilfield production, real-time online monitoring and optimization control of remote and dispersed oil well production processes have been achieved, and a new intelligent oilfield production model integrating remote measurement, fault diagnosis and energy-saving optimization with unmanned intervention has been initially formed, so as to drive the high-quality development of the oil and gas industry through digital transformation.

The World Internet Conference (WIC) was established as an international organization on July 12, 2022, headquartered in Beijing, China. It was jointly initiated by Global System for Mobile Communication Association (GSMA), National Computer Network Emergency Response Technical Team/Coordination Center of China (CNCERT), China Internet Network Information Center (CNNIC), Alibaba Group, Tencent, and Zhijiang Lab.