- Home

- Media Center

-

Events

- Wuzhen Summit

- Regional Forums

- Practice Cases of Jointly Building a Community with a Shared Future in Cyberspace

- World Internet Conference Awards for Pioneering Science and Technology

- The Light of Internet Expo

- Straight to Wuzhen Competition

- Global Youth Leadership Program

- WIC Distinguished Contribution Award

- Membership

- Research & Cooperation

- Digital Academy

-

Reports

- Collection of cases on Jointly Building a Community with a Shared Future in Cyberspace

- Collection of Shortlisted Achievements of World Internet Conference Awards for Pioneering Science and Technology

- Reports on Artificial Intelligence

- Reports on Cross—Border E—Commerce

- Reports on Data

- Outcomes of Think Tank Cooperation Program

- Series on Sovereignty in Cyberspace Theory and Practice

- Other Achievements

- About WIC

- 中文 | EN

Collection: ARGO - Autonomous inspection of rolling stocks

Next Generation Robotics Company

Introduction

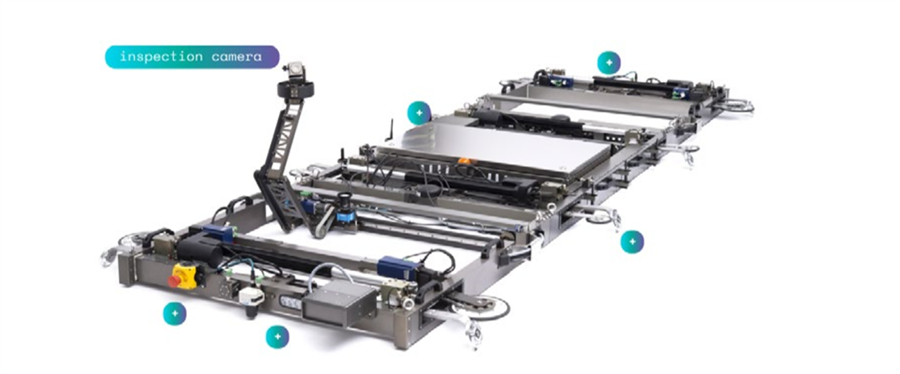

ARGO is a new railcar inspection robot manufactured by Next Generation Robotics for autonomous safety inspections of general railcars. Predictive maintenance and high-precision repetitive operations are performed through artificial intelligence algorithms, which in turn replace current visual inspection procedures to improve train safety.

Predictive maintenance assisted by artificial intelligence for standard track

ARGO is a new robot that performs autonomous safety inspections of trains. ARGO can replace the current visual inspection procedures of pit rails and inspection pits carried out by operators at the maintenance site in order to improve train safety and enable higher-frequency and higher-precision operations through automation and digitization of relevant data. The robot has been devised to be seamlessly integrated in the railway infrastructure, since it can run inside the tracks and is therefore able to perform safety inspections of the train from the bottom, checking critical parts like brake pads, bolts, brake disks, train joints, etc. by means of artificial intelligence algorithms. Benefiting from the combination of robotics and artificial intelligence, ARGO enables predictive maintenance processes.

Covered by more than 5 international patents, currently successfully commercialized in the European market

The robot is equipped with sophisticated computer vision algorithms that can automatically recognize a large number of important parts and faults, and perform automatic inspections to ensure the safety of the train. The robot can be adapted to any standard railroad and does not even require trains to be driven onto specialized inspection pits. This allows safety inspections to be carried out at every station, at every pit, no longer limited by space. And, because the robot is equipped with LIDAR sensors, it can interact safely with humans. At present, the robot has been patented and commercialized by the Next Generation Robotics in the European market. In the future, this technology will formally enter the international market, and do its best for the development of world's railroad industry.

In the future, this technology will officially enter the International market and join the development process of the railway industry

In the context of Industry 4.0 and digitalization, ARGO Robotics is committed to perfecting the predictive maintenance capabilities required by Industry 4.0 in three areas: digital data collection, artificial intelligence data analysis and repetitive operations. Firstly, digital data collection. The HQ camera for visual inspection is used to observe and collect data from all directions and angles on the bottom of the train. Afterwards, the results are analyzed by artificial intelligence through intelligent navigation and artificial vision algorithms. Finally, a robotic solution for precise positioning of the sensors is created by repeating the process several times. This solution will save manpower costs and resources, improve the efficiency of train inspections, and will be commercialized locally in China, joining World's Industry 4.0 and digital development process.

The World Internet Conference (WIC) was established as an international organization on July 12, 2022, headquartered in Beijing, China. It was jointly initiated by Global System for Mobile Communication Association (GSMA), National Computer Network Emergency Response Technical Team/Coordination Center of China (CNCERT), China Internet Network Information Center (CNNIC), Alibaba Group, Tencent, and Zhijiang Lab.