More manufacturers in WEF Global Lighthouse Network

By ZHAO RUIXUE in Jinan| (China Daily)| Updated : 2024-10-11

Print Print

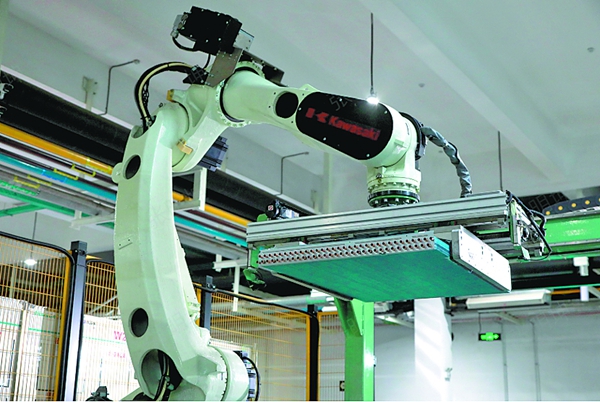

The production line of Hisense Hitachi Air-conditioning Systems Co Ltd in Qingdao, Shandong province. [CHINA DAILY]

Three manufacturers in Qingdao, Shandong province, have been selected as new members of the Global Lighthouse Network by the World Economic Forum, taking the city's total to seven such lighthouses and making it, alongside Suzhou, Jiangsu province, one of the two cities in China with the most lighthouse factories.

This, experts said, showcases the growing manufacturing capabilities of the coastal city and reflects the pursuit of cutting-edge technologies and sustainable development by Chinese industries.

Hisense Hitachi Air-conditioning Systems Co Ltd in Qingdao implemented more than 40 use cases of the Fourth Industrial Revolution technologies, boosting the speed of product development by 37 percent, increasing labor productivity by 49 percent and reducing manufacturing costs by 35 percent, according to a report on the WEF's official site.

From pioneering unmanned heat exchangers to automated welding, Hisense Hitachi has created over 40 advanced application scenarios, with more than 20 technologies being industry firsts.

"This not only provides a competitive edge in the market but also injects new vitality and momentum into high-quality industrial development," said Zhuang Junjie, director of the automation division for assembly line at Hisense Hitachi.

The company has developed over 40 sets of adaptive automated welding equipment, which are widely used across various welding scenarios within the factory.

"In multiple stages, we have implemented unmanned inspections, packaging, and critical quality testing. Our overall efficiency is approximately 23 percent higher than the industry average," said Zhuang.

Meanwhile, led by intelligent digitalization, Tsingtao Brewery has earned recognition as the world's first "sustainability lighthouse" in the food and beverage industry, according to the brewery.

By enhancing the integration of technologies like industrial internet and IoT, the century-old factory has effectively addressed production constraints and improved overall resource utilization, energy consumption, and ecological performance, it said.

According to the WEF report, industrial beer brewing is traditionally high-energy and carbon-intensive. Tsingtao Brewery leveraged advanced algorithms and IoT to deploy 25 use cases aimed at reducing energy and carbon intensity in beer production. The factory has achieved a 25 percent reduction in unit energy consumption.

In addition, Qingdao Haier (Jiaozhou) Air Conditioner Co Ltd has also been shortlisted in the GLN, making global brand Haier the Chinese company with the largest number of lighthouse factories worldwide, according to the company.

Exporting products to 130 countries and regions, the factory has not only met surging global demand, but also leveraged big data and advanced algorithms to resolve issues related to delayed responses in research and development, delivery, and after-sales service.

Xi's Moments

Xi's Moments  Shandong gains remarkable results in promoting high-quality development

Shandong gains remarkable results in promoting high-quality development  Discover magnolia blossoms at Shandong University

Discover magnolia blossoms at Shandong University